Products

TGV Glass Core

TGV Glass Core

Next-Gen High-Density Interconnect Solution

LADY(Laser Arrow Decomposition Yield)

Ingentec applies fine chemical distillation technology to produce ultra- high purity specialty gases, which are introduced into advanced processes such as etching, film removal, and precision glass drilling.

NICE-LADY(Nano In-Situ Consolidation Engineering)

NICE LADY technology enables in situ nano metal filling within TGV vias. By utilizing metal nanoparticles, it achieves highly dense metallization structures. This innovation is ideal for high frequency and RF components, significantly enhancing interconnect reliability and signal integrity.

LADY-CPT(Copper Pillar Technology)

LADY CPT technology transforms Through Glass Via (TGV) structures by filling copper pillars to create micron scale metal pin arrays. This breakthrough enables ultra fast signal transmission, unlocking new possibilities for advanced packaging, heterogeneous integration, and high frequency/high speed applications.

Optical Fiber Array Aligner

A High-Precision Glass Platform for Next-Generation CPO Fiber Alignment

Leveraging the TGV Glass Core platform and LADY process technology, this solution delivers highly uniform micro-structured features and a stable fiber array Aligner, suitable for CPO (Co-Packaged Optics) electro-optical integration with silicon photonics and other optical engines.

TVG products are operated under the trademark of INGENTEC® or INGENUITY®, and more application of Vapor Etching is under developed.

If you want to buy this product, please contact us!

Next-Gen High-Density Interconnect Solution

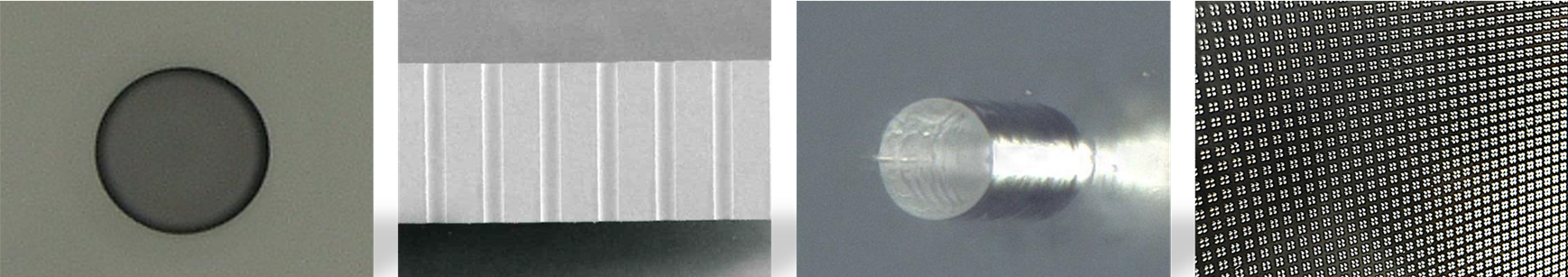

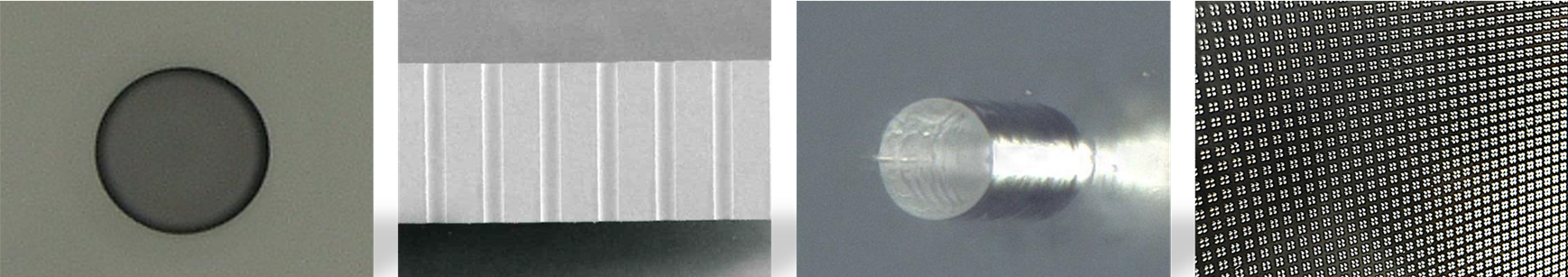

LADY(Laser Arrow Decomposition Yield)

Ingentec applies fine chemical distillation technology to produce ultra- high purity specialty gases, which are introduced into advanced processes such as etching, film removal, and precision glass drilling.

- Micro laser spot technology enables high-density through-via interconnections.

- Vapor-phase dry etching significantly accelerating via formation efficiency

- Highly uniform via dimensions, vertical profiles, and smooth inner walls.

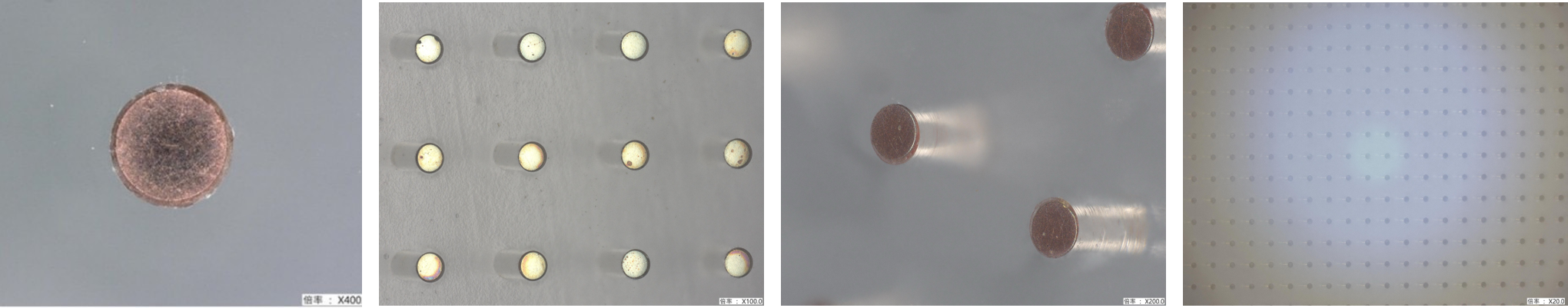

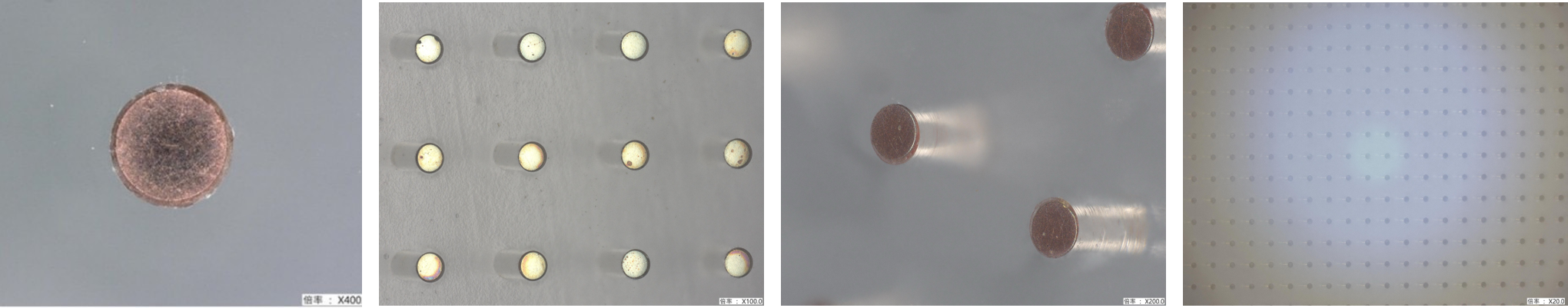

NICE-LADY(Nano In-Situ Consolidation Engineering)

NICE LADY technology enables in situ nano metal filling within TGV vias. By utilizing metal nanoparticles, it achieves highly dense metallization structures. This innovation is ideal for high frequency and RF components, significantly enhancing interconnect reliability and signal integrity.

LADY-CPT(Copper Pillar Technology)

LADY CPT technology transforms Through Glass Via (TGV) structures by filling copper pillars to create micron scale metal pin arrays. This breakthrough enables ultra fast signal transmission, unlocking new possibilities for advanced packaging, heterogeneous integration, and high frequency/high speed applications.

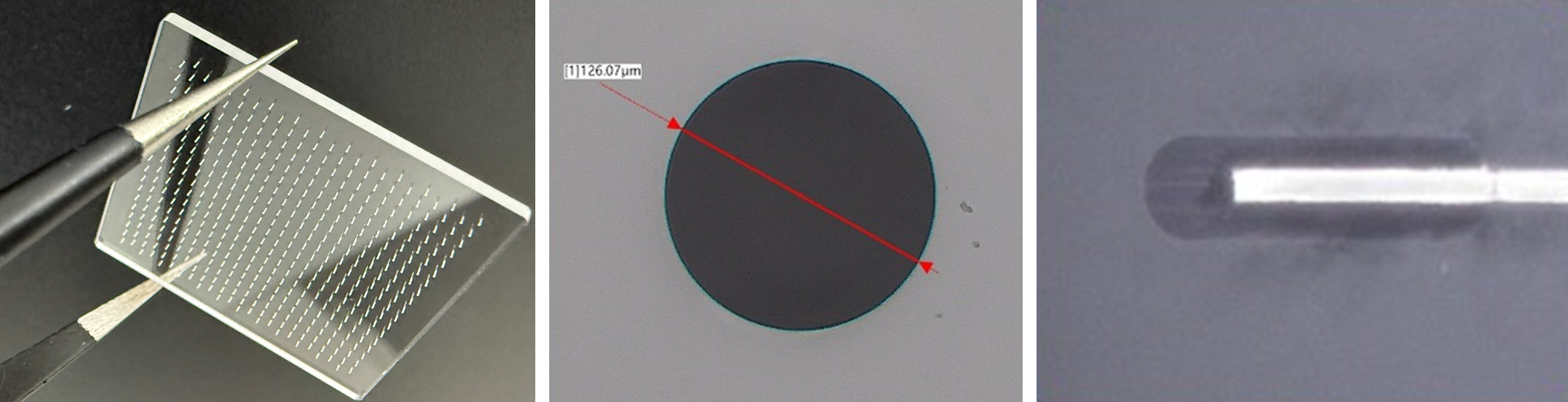

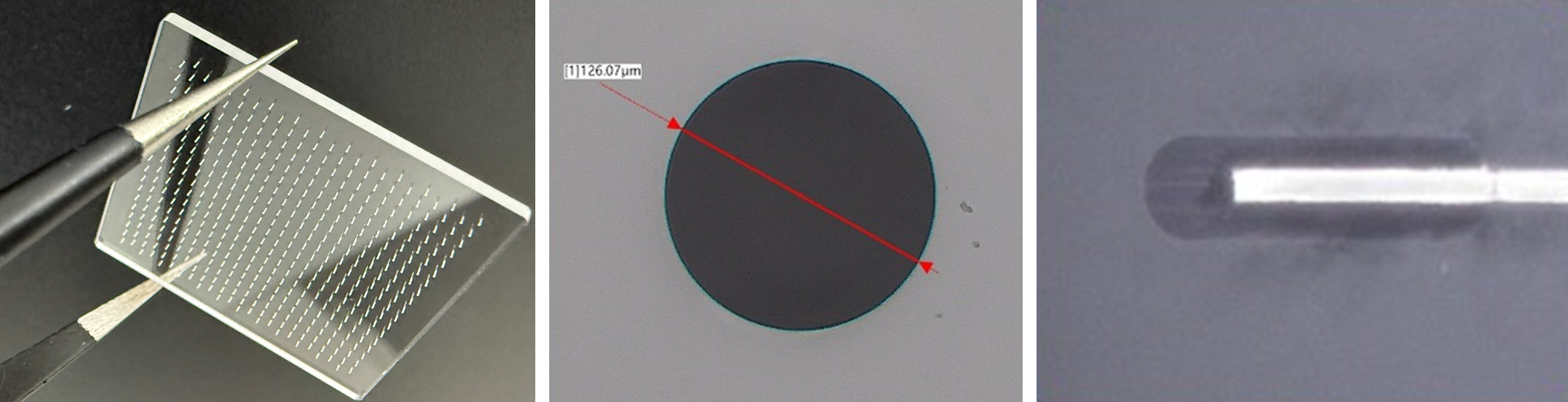

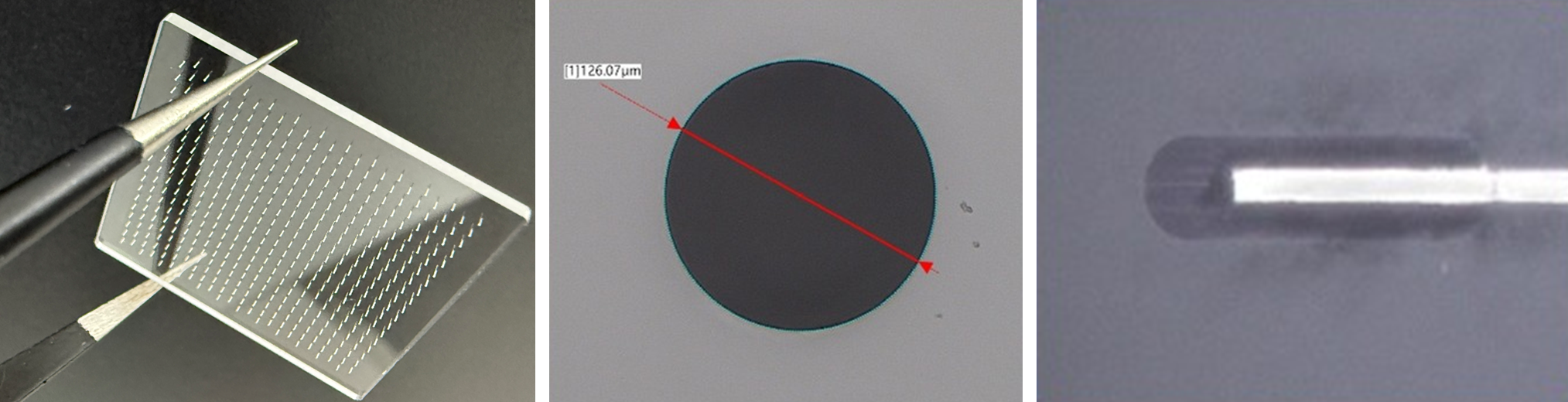

Optical Fiber Array Aligner

A High-Precision Glass Platform for Next-Generation CPO Fiber Alignment

Leveraging the TGV Glass Core platform and LADY process technology, this solution delivers highly uniform micro-structured features and a stable fiber array Aligner, suitable for CPO (Co-Packaged Optics) electro-optical integration with silicon photonics and other optical engines.

- High-Precision Fiber Alignment:Enabled by LADY (Laser Arrow Decomposition Yield) laser modification and proprietary vapor etching, delivering highly uniform micro-via structures for accurate fiber alignment and improved optical coupling efficiency.

- High-Density, High-Aspect-Ratio Design:Supports small via diameters, fine pitch, and high aspect ratios to meet the requirements of high-density CPO fiber array integration.

- Low-Damage, High-Reliability Glass Structure:Non-mechanical processing minimizes material damage and residual stress. Combined with the low CTE of glass, it ensures excellent dimensional and optical-axis stability for long-term operation.

TVG products are operated under the trademark of INGENTEC® or INGENUITY®, and more application of Vapor Etching is under developed.

If you want to buy this product, please contact us!

.png)